As the digital revolution continues to reshape the world around us, few innovations have been as impactful as those in the field of digital fabrication. At the forefront of this movement is Carbide 3D, a company that’s been dedicated to empowering hobbyists, makers, and professionals alike. Their tools and software are not just about engraving or cutting; they’re about turning visions into reality.

A Closer Look: What Sets Carbide 3D Apart?

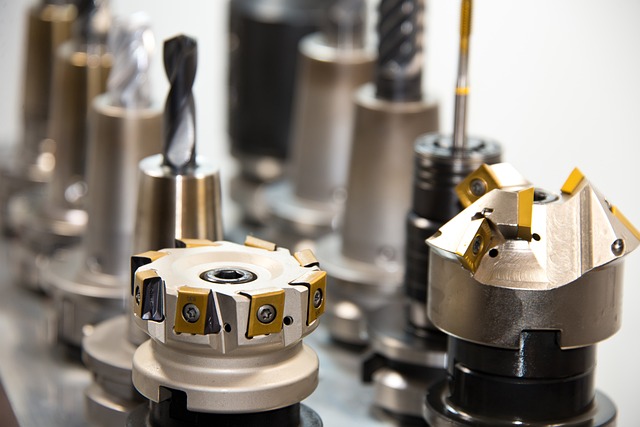

Carbide 3D’s product lineup is commendably diverse, catering to a range of needs and skill levels. From their Shapeoko CNC machines designed for precision and repeatability to the Nomad 883 Pro, a machine praised for its power and accuracy in a compact form factor, there’s a tool for every project.

It’s not just the hardware that shines. The company’s suite of software solutions, such as Carbide Create and Carbide Motion, ensures a seamless experience from design to execution. They’re user-friendly and come with extensive support documentation, which is a nod to Carbide 3D’s commitment to user education and empowerment.

User Experience and Customer Support

One key area where many tech-oriented companies falter is customer support. Thankfully, Carbide 3D doesn’t belong to that category. Their online community forum is bustling with activity, where both company representatives and experienced users pitch in to help troubleshoot issues, share tips, and celebrate successes. The forum also serves as a testament to the brand’s community-driven ethos.

Moreover, the tutorial section of their website is a goldmine. Whether you’re a newbie struggling with your first CNC project or a seasoned user exploring advanced techniques, there’s content tailored for you. This emphasis on education underlines the fact that Carbide 3D is not just selling products; they’re fostering a community of makers.

Practical Applications and Real-World Impact

Digital fabrication tools like those offered by Carbide 3D are redefining how we approach design and manufacturing. From creating intricate jewelry pieces, wooden crafts, to prototyping revolutionary product designs – the possibilities seem boundless.

Perusing through the project gallery on their website gives you a snapshot of this creative explosion. It’s inspiring to see how diverse the Carbide 3D user base is and the range of projects they undertake. It reaffirms the belief that with the right tools, creativity knows no bounds.

Areas of Improvement?

No company is without its areas of growth, and Carbide 3D is no exception. While their machines are robust and reliable, some users have pointed out the steep learning curve, especially for those new to digital fabrication. While the company does offer extensive resources, perhaps more hands-on workshops or webinars could further bridge this gap.

Shipping and delivery timelines, especially for international customers, can also be a tad unpredictable. Given the current global logistics scenario, this is understandable, but it’s an area where there’s room for refinement.

In an era where most consumer products are mass-produced, there’s a growing demand for customization and unique designs. This is where the prowess of digital fabrication steps in, granting individuals and businesses the power to create tailored solutions. Carbide 3D is not just a tool provider but acts as the bridge between imagination and tangible creations.

Price Point: Accessibility Meets Quality

When assessing any product, cost invariably becomes a point of contention. Carbide 3D, however, manages to strike a good balance. Compared to other high-end CNC machines and fabrication tools in the market, their products sit comfortably in a range that doesn’t break the bank but also doesn’t compromise on the quality and precision they deliver.

This competitive pricing strategy, combined with the extensive resources they offer, makes Carbide 3D an appealing option for both amateurs just dipping their toes in the world of CNC machining and seasoned professionals looking for reliable equipment.

Sustainability and Eco-Friendliness

Another noteworthy aspect of Carbide 3D is its commitment to sustainable practices. While the website does not heavily market this facet, digging deeper reveals that their machines are designed for durability, reducing the frequency of replacements and thereby lessening electronic waste. Additionally, by empowering individuals to create products on demand, there’s a reduction in the mass production of items that might eventually end up as waste.

Collaborations and Partnerships

The strength of any company often lies in its ability to forge strong partnerships. Carbide 3D’s collaboration with other software and hardware entities indicates its dedication to providing an integrated experience for its users. By ensuring compatibility with popular design tools and software, they ease the transition for users who might be migrating from different platforms or integrating Carbide 3D tools into their existing workflow.

A Dive into Their Product Range

While the Shapeoko and Nomad series grab most of the limelight, delving into Carbide 3D’s product listings exposes a plethora of accessories and tools. From end mills suited for specific materials to touch probes that enhance precision, the company ensures that users have everything they need to jumpstart their projects.

Moreover, their frequent updates and product launches signal a brand that’s constantly innovating. It’s not a company that rests on its laurels but is continuously iterating, improving, and responding to user feedback.

Navigating the expansive realm of digital fabrication can often be overwhelming, but with stalwarts like Carbide 3D at the helm, the journey becomes significantly more manageable. They don’t merely offer products; they provide holistic solutions. From their top-tier CNC machines to the exhaustive suite of accessories and supportive resources, Carbide 3D emphasizes quality, innovation, and user-centricity. Whether you’re a budding hobbyist or a seasoned professional, their offerings serve as a testament to the company’s commitment to fueling creativity and precision in the digital fabrication arena.